AMS ASME ASTM ya inconel625 alloy navigator

AMS ASME ASTM ya inconel625 alloy navigator,

625 Alloy , Inconel 625 Utubari , Inconel 625 Inkoni , Inconel 625 urupapuro plate Isahani ya Inconel 625 plate Inconel 625 strip , Inconel 625 coil,

Amazina rusange yubucuruzi: Inconel 625, UNS NO6625, Nickel Alloy 625, Alloy 625, Nickel 625, W.Nr.2.4856

Inconel Alloy 625 ni magnetique, ruswa kandi irwanya okiside, nikel-chromium.Imbaraga nyinshi za Inconel 625 nigisubizo cyo gukomera kwa molybdenum na niobium kuri nikel chromium base ya alloy.Inconel 625 ifite imbaraga zo kurwanya ibintu byinshi bidasanzwe byangiza ibidukikije harimo ingaruka zubushyuhe bwo hejuru nka okiside na karburizasi.Imbaraga zidasanzwe nubukomezi bwubushyuhe buva ku bushyuhe bwa kirogenike kugeza ku bushyuhe bwo hejuru bugera kuri 2000 ° F (1093 ° C) bikomoka cyane cyane ku ngaruka zikomeye z’ibisubizo by’ibyuma bitavunika Columbium na molybdenum muri materique ya nikel-chromium.

Inconel 625 Ibigize imiti

| % | Ni | Cr | Fe | Mo | Nb + Ta | Co | C | Mn | Si | S | Al | Ti | P |

| Min. | 58.0 | 20.0 | - | 8.0 | 3.15 | - | - | - | - | - | - | - | - |

| Icyiza. | - | 23.0 | 5.0 | 10.0 | 4.15 | 1.0 | 0.1 | 0.5 | 0.5 | 0.015 | 0.4 | 0.4 | 0.015 |

Inconel 625 Ibintu bifatika

| Ubucucike | 8.4 g / cm³ |

| Ingingo yo gushonga | 1290-1350 ℃

|

Inconel 625 Ibikoresho bisanzwe bya mashini

| Imiterere | Imbaraga Rm N / mm² | Tanga imbaraga Rp 0. 2N / mm² | Kurambura Nka% | Gukomera kwa Brinell HB |

| Umuti | 827 | 414 | 30 | 20220 |

Inconel 625 Ibipimo nibisobanuro

AMS 5599, AMS 5666, AMS 5837, ASME SB 443 Gr 1, ASME SB 446 Gr 1, ASTM B 443 Gr 1, ASTM B 446 Gr 1, EN 2.4856, ISO 15156-3, NACE MR0175-3,

UNS N06625, Werkstoff 2.4856

| Umugozi | Urupapuro | Strip | Inkoni | Umuyoboro | |

| AMS 5599, AMS 5666, AMS 5837, AMS 5979, ASTM B443 | ASTM B443 | AMS 5599, AMS 5979, ASTM B443 | ASTM B 446 SAE / AMS 5666, VdTÜV 499 | Umuyoboro utagira ikizinga | Umuyoboro |

| ASTM B 444 / B 829 & ASME SB 444 / SB 829SAE / AMS 5581 | ASTM B704 / B751 ASME SB704 / SB 751ASTM B705 / B 775, ASME SB 705 / SB 775 | ||||

Inconel 625 Ibicuruzwa biboneka mubyuma bya Sekonic

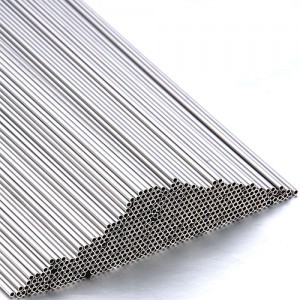

Inconel 625 Utubari & Inkoni

Utubari tuzengurutse / Utubari twa Flat / Utubari twa Hex, Ingano Kuva 8.0mm-320mm, Yifashishijwe kuri bolts, yihuta nibindi bice by'ibikoresho

Inconel 625 insinga

Tanga insinga zo gusudira hamwe ninsinga zamasoko muburyo bwa coil hanyuma ugabanye uburebure.

Inconel 625 urupapuro & isahani

Ubugari bugera kuri 1500mm n'uburebure bugera kuri 6000mm, Ubunini kuva 0.1mm kugeza 100mm.

Inconel 625 itagira umuyoboro & Welded pipe

Ingano yubunini hamwe nigipimo cyihariye gishobora kubyara natwe kwihanganira bito

Inconel 625 strip & coil

Imiterere yoroshye nuburyo bukomeye hamwe na AB igaragara hejuru, ubugari bugera kuri 1000mm

Inconel 625

Alloy 625 turashobora gutanga bolts, Imbuto nibindi bifata nkibisabwa abakiriya

Inconel 625 Ibiranga:

1.Imbaraga zo hejuru-guturika

2.Imisozi irwanya 1800 ° F.

3. Kurwanya umunaniro mwiza

4.Gusudira neza

5.Kurwanya kurwanya chloride hamwe no kwangirika

6.Immune kuri chloride ion guhangayikishwa no kwangirika

7.Kurwanya amazi yinyanja haba mubihe bitemba kandi bidahagaze kandi mubi

Inconel 625 Umwanya wo gusaba :

•Sisitemu yo gutwara indege

•Sisitemu yo gusohora moteri

•Sisitemu yo gusunika-gusubiza inyuma

•Inzogera hamwe no kwaguka

•Turbine impeta

•Umuriro

•Ibigize amazi yo mu nyanja

•Ibikoresho bya chimique bitunganya aside ivanze haba okiside no kugabanya.

Isosiyete yacu Ifishi y'ibicuruzwa

Utubari & Inkoni

Inconel / Hastelloy / Monel / Haynes 25 / Titanium

Tube idafite Tube & Welded Tube

Nickel / Titanium Alloy tubes, U-bend / guhanahana ubushyuhe

Bolt & Nuts

Inconel 601 / Hastelloy C22 / Inconel x750 / Inconel 625 ect

Urupapuro & Isahani

Hastelloy / Inconel / Incoloy / Cobalt / Tianium

Strip & Foil

Hastelloy / Inconel / invar / yoroshye ya magnetiki Alloys ect

Ubushyuhe bwo hejuru

Inconel 718 / Inconel x750 / Nimonic 80A

Umugozi & Welding

Cobalt Alloy wire, Nickel alloy wire, Tianium Alloy wire

Imyenda idasanzwe

Monel 400 / Hastelloy C276 / Inconel 718 / Titanium

Amavuta ya Tube Hanger

Inconel x750 / Inconel 718 / Monel 400 ect

Nickel Ashingiye

Ibikoresho byo gusudira

Amavuta ya Cobalt

Ibyuma bidasanzwe

Amavuta meza

Amavuta ya Titanium

Urashaka kwiga byinshi cyangwa kubona amagambo?

Menyesha

Nibihe bikoresho 625 bivanze?Nikel - ishingiye ku mavuta hamwe Ni - Cr - Mo.

Ibigize imiti ya Alloy 625: Chromium (Cr) 20.0-23.0, Icyuma (Fe) <5.0, (Al) & lt;0.4, Silicon (Si) <0,50 manganese (Mn) <0.50, Nickel (Ni) 258, sulfure (S) <0.015, Cobalt (Co) <1.0, (Mo) 8.0-10.0, Titanium (Ti) <0.4, Fosifore (P) <0.015, (Nb) 3.15-4.15, Carbone (C) <0.01.

625 Amavuta aranga okiside nziza kandi irwanya ruswa, imbaraga zidasanzwe no gukomera, kurwanya umunaniro mwiza, guhinduka cyane, no gusudira neza.Irashobora kugumana imbaraga nubukomezi aho ariho hose kuva ubushyuhe buke kugeza 2000 ° F.Bitewe no gukomera kwinshi kwa alloy 625, ubwinshi bwubukonje burashobora gusaba annealing mugihe cyose gikonje.Amavuta akoreshwa cyane muri moteri yindege hamwe nibindi bikorwa byo mu kirere.